In an industry as big and important as the steel casting industry is, technological innovations are not only desired, but they are also expected and necessary in order to meet the wants and needs of a modern man. This type of craft represents a base frame of countless other segments of everyday life that would otherwise be nothing more than a part of our imagination. If the modernized steel casting industry were to be left out of the up-to-date equation imposed by the desires and necessities of a modern man, the world as we know it would be utterly different.

The Industry

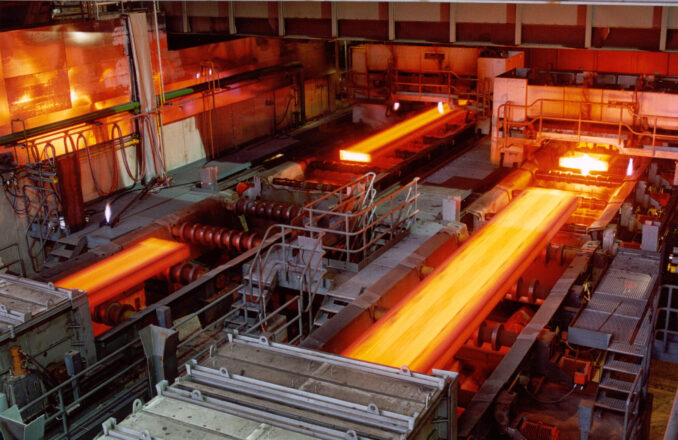

Source:globalwoodmarketsinfo.com

There are various procedures any casted part needs to go through before it reaches the final point of the casting cycle. What we should never forget is that this particular craft has been developing alongside humankind and it is closely related to the global progress of man both as an individual and as a part of society. Even though the steel industry is not popularized via popular media, it does not diminish the fact that experts work on different improvements making steel casting more productive and at the same time, less contaminating industry.

Keeping up with the trend imposed by both the demand and the competition is the only way to survive in the steel casting industry. It is not a short-term race, more rather it is a marathon. Therefore, the ongoings on the global steel market do not surprise anyone and the supremacy demonstrated by Japanese companies is nothing more than a result of many years of outstanding innovations. Side by side with the Japanese are American industrial giants and the rest of the world watches closely for the next big thing to be brought to life. Of course, the Chinese and Russians are next in line when we talk about capacity and productivity, but in terms of the innovations, although they closely fall behind, they are also doing their best to catch up with the competition.

The Progress

Although the most revolutionary time in the steel casting industry played out in the 19th and 20th century, there is still a lot of room for improvement and the advancements in steel casting are being worked on constantly. Innovations are particularly being introduced in the AI sector since former generations of steel engineers did not have the luxury of automatized processes and high-end technologies. Namely, in contemporary times modern men of craft have no trouble reaching temperatures that were unimaginable back in the old days. Also, they can sustain a certain temperature for as long as they want, thanks to modern furnaces and oxygen utilization. But the need for innovations does not stop there.

The Furnace

The launch of the arc furnace was considered to be the final form of that time since the productivity it enabled then was a major step towards success. Nowadays, the demand dictates the rules, so in order to improve contemporary standards, higher production is required as much as the reduction of the production costs. That can be only potentiated in accordance with the entire industry and focus on both overall and individual industry segments.

The Molds

The importance of molds used in the steel casting industry is not to be neglected when we bring the innovation of actual standards in question. Molds have been used since the earliest days of steel casting and the philosophy about the practice hasn’t really changed over the years. What did change is related to the material and the shape, making new designs superior to the former models in numerous aspects. Exactly at this field are the eyes of the world focused since both major companies and accredited universities dedicate their time and thought to this issue.

Source:generalkinematics.com

The Importance of Materials

When we talk about materials used, they are as important as their casting process. Namely, it is important to highlight that an iron material is called steel when it contains two percentages of carbon. Therefore, pure iron is not likely to be found in steel products, unless that type of business venture is demanded by a customer. The point of mixing different materials in the process of steel casting is to enhance the primal form and make it more suitable for its particular purpose.

The Process

An important innovation in the field of material innovation is manganese steel, and it is produced under strictly timed operations. First what is to be done when making manganese steel is to simulate the pouring of the liquid iron. Afterward, the technical sector designs the molds according to the drawings provided by the customer, and after that is done, the quality and the measures are checked by the quality department. Materials used for molds are usually wood for single usage and plastic and metal for mass production. The metal pouring comes only after the raw materials are inspected and wax models are set by regulating waxing pressure and making sure holding time is right. Only after the shells are checked and temperature, humidity, and various substances are verified, metal pouring can start. Finally, the product undergoes cleaning and is exposed to heat treatment, in order to obtain the required firmness, and after it is inspected one more time it is ready for delivery. If this process of manganese steel casting intrigues you, feel free to read more about it!

Continuous Casting

Another groundbreaking innovation was the implementation of the continuous steel casting method. This enables the liquified hot iron to be continuously cast straight onto dense slabs, from the refining vessel. This process speeds up the procedure a lot and what is even better, has enough place for improvement in the following years.

Belt-Casting

Source:generalkinematics.com

This is the version of a continuous steel casting method, only made more productive with the implementation of double rolls and it implies working with partially liquid iron in the process. Not only does it speed the whole process up in a way rarely seen before, but it also enlarges the production capacity and saves both time and money.

Hopefully, the aforementioned facts have brought you closer to the actual trends and certain processes in the steel casting industry. It is a live industry that keeps evolving with every new day and stands shoulder to shoulder with the advancement of mankind. Therefore, the industry will continue to grow and provide new means of production until absolute perfection is achieved.