In the realm of electrical projects, where precision and reliability are paramount, pigtail connectors emerge as unsung heroes, streamlining complex wiring tasks and ensuring seamless electrical connections. Whether you’re a seasoned electrician or a DIY enthusiast, understanding how pigtail connectors work can significantly simplify your projects.

The Basic Components

At their core, pigtail connectors are simple yet ingenious devices designed to join multiple wires together. They consist of a short, insulated wire with a pre-attached connector on one end. The connector can take various forms, such as wire nuts, crimp connectors, or even soldered joints, depending on the specific application.

Benefits of Using Pigtail Connectors in Wiring

Source: everydayhomerepairs.com

They offer a slew of advantages that make them indispensable in electrical work. Firstly, they enhance safety by minimizing the risk of loose connections, which can lead to electrical fires or equipment damage. Additionally, they facilitate easy troubleshooting and maintenance, allowing for quick wire replacement or upgrades without disrupting the entire circuit.

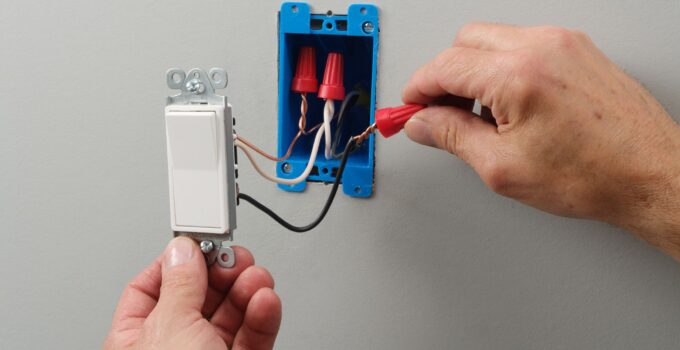

Step-by-Step Guide on How to Install

Installing Pigtail Connectors may seem intimidating, but with the right guidance, it becomes a straightforward process. Here’s a step-by-step guide to help you get started:

Gather Your Tools: You’ll need wire strippers, a wire cutter, connectors, and electrical tape or heat shrink tubing.

Prepare the Wires: Strip the insulation from the wires you want to connect and trim them to the same length.

Twist the Wires Together: Align the stripped ends of the wires and twist them tightly together in a clockwise direction.

Attach the Pigtail Connector: Slide it over the twisted wires and secure it using the appropriate method (wire nut, crimping, soldering, etc.).

Insulate the Connection: To prevent electrical hazards, wrap the connection with electrical tape or apply heat shrink tubing if required.

Common Types and Their Applications

They come in diverse types, each tailored to specific electrical applications. Wire nuts, a common choice in residential wiring, offer secure twist-on connections. Crimp connectors, favored in automotive and industrial settings, provide reliable, vibration-resistant joints. Soldered pigtails, often used in electronics, offer durability but require skilled soldering. Push-in connectors are quick and easy, commonly seen in modern residential wiring. These variations cater to a wide array of scenarios, from home electrical upgrades to automotive repairs and intricate electronic projects. Understanding the types and their applications allows for precise and efficient use, ensuring reliable electrical connections across various contexts.

Safety Precautions When Working

Safety precautions are paramount when working with them to prevent electrical accidents. Always begin by turning off the power to the circuit you’re working on, reducing the risk of electric shocks. Ensure proper insulation by covering connections with electrical tape or using heat shrink tubing, minimizing the possibility of exposed wires causing short circuits or electrical fires. Lastly, verify the compatibility of connectors with the wire size and application, preventing overheating and electrical hazards. By adhering to these precautions, you create a safer working environment and reduce the potential risks associated with handling them in projects.

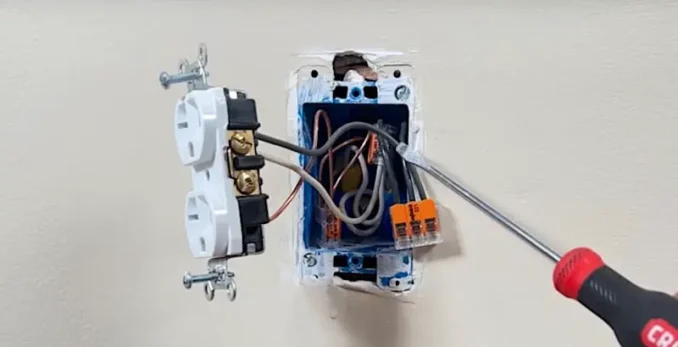

Troubleshooting Issues with Pigtail Connectors

Source: jlconline.com

Troubleshooting issues is essential for maintaining safe and reliable connections. Start by inspecting the connectors for loose or damaged components. If you find any, resecure or replace them immediately to prevent further problems.

Testing for continuity using a multimeter is a valuable step to identify hidden issues within the wires or connectors. This ensures that electrical flow is uninterrupted and safe.

Additionally, verifying compatibility with the application is crucial. Ensure you’ve used the correct type for the job, as mismatched connectors can lead to overheating or connection failures.

Pigtail Connectors vs. Other Electrical Connection Methods

While they offer numerous advantages, it’s essential to compare them to other connection methods:

Pigtail Connectors vs. Wire Nuts: They provide a more secure and long-lasting connection compared to traditional wire nuts.

Pigtail Connectors vs. Crimping: Crimped connections are more commonly used in automotive and industrial applications, offering excellent durability.

Pigtail Connectors vs. Soldering: Soldered connections are highly reliable but require more skill and time compared to them.

Maintenance Tips

Proper maintenance is essential to ensure the longevity and reliability of electrical connections. Regular inspections are paramount; periodically check for signs of wear, corrosion, or loose wires. If any issues are detected, address them promptly to prevent potential hazards. Tighten loose connections as needed to maintain integrity. In critical or high-stress applications, consider upgrading them for added safety and durability.

Furthermore, keeping them clean and free from dirt or debris helps prevent deterioration over time. Apply anti-corrosion solutions if applicable, especially in outdoor or damp environments. By following these maintenance tips, you can maximize the lifespan and ensure that your electrical connections remain safe and reliable for years to come, minimizing the need for costly repairs or replacements.

Real-World Examples of Pigtail Connector Usage

In several practical applications, they are often used. They ease renovations by allowing the hassle-free installation of new outlets and switches to in-home wiring. They are essential in the automobile sector for fixing broken wiring harnesses and ensuring cars stay safe and functioning. Furthermore, they are important components in electronic projects because they allow for the secure soldering of components onto circuit boards, which is critical for the myriad of electronic gadgets we use every day. Their adaptability extends to industrial settings, where they are used in machinery and equipment connections to improve dependability and simplicity of maintenance. These real-world examples show the critical function they play in simplifying connections in a variety of areas, emphasizing their significance and use.

Conclusion: Simplifying Electrical Projects

Source: youtube.com

In the intricate world of electrical projects, they stand as indispensable tools that simplify complex wiring tasks. Their straightforward design, versatility, and reliability make them a valuable asset for professionals and DIY enthusiasts alike. By mastering the art of pigtail connectors, you not only enhance the safety and efficiency of your electrical work but also gain the confidence to tackle a broader range of projects with ease. So, the next time you embark on a venture, remember that pigtail connectors are your trusted allies in simplifying the intricate web of wires and circuits.