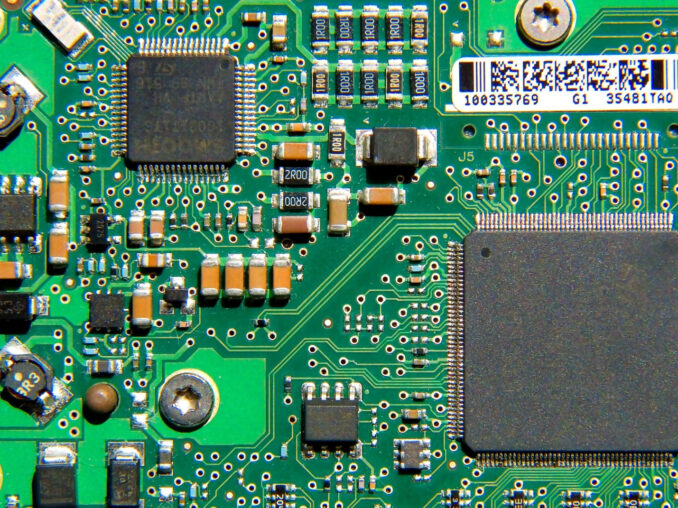

Technology has come a long way in these past 20 or 30 years. Especially the technology of electronics. In the past, even the simplest pieces of electronics were very expensive. This was mostly because the industry was still very young. A simple remote control would be 10 or 20 times the size when compared to the ones that we have at home today. But, by improving the technology of creating printed circuit boards or PCBs, we can now manufacture and assemble much smaller, faster, and more efficient devices.

However, even with the knowledge and technology that we have today, there are still some hidden “secrets” or tips that could help any business save money and be more efficient when manufacturing printed circuit boards. There are a lot of things you could change with the assembly to make the entire process much simpler.

These kinds of tips can be very useful, especially for new businesses in this industry. I hope that these tips that I am going to share with you will be useful and will help you be more efficient and factoring PCBs.

Source:predictabledesigns.com

Aim to keep the PCB as small as possible

This one might seem a bit obvious to you, but I think it is important to constantly remind yourself and your employees that the aim of your company is to make as much profit as possible and that is best done by reducing the size of your printed circuit boards. The bigger they get, the more money you will have to spend. Obviously, a new business will not have the budget to handle such large boards.

Thankfully, with the technology we have today, we can make one of the smallest PCBs ever. But, if you want to achieve that, you will need to have the right equipment, experts, and knowledge of this technology. Once you get a hold of these three main things, your company will finally be able to keep the size of your PCBs as small as possible.

Of course, it is also important to consider the factors that you want to create quality products. So, you will need to find that balance between complexity, quality, and size if you want to provide a good product for your customers.

Use quality materials

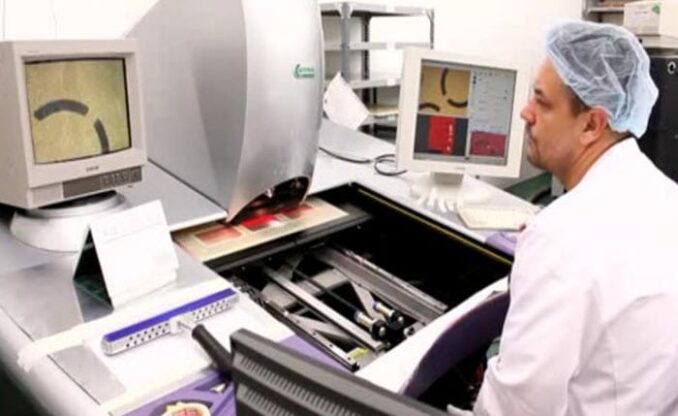

Source:eurocircuits.com

This is another very obvious piece of advice, but I think that many companies tend to forget that it is very important to stick with quality instead of quantity. I understand the fact that you can bring a much bigger profit if you cut down on costs of materials, but that could hurt your company in the long run. Once you start producing lower quality products, there is a possibility that your customers will be disappointed with your product and will ultimately switch to a different company. This way, you are essentially losing profit.

So, when it comes to printed circuit boards, I always advise everyone to stick to using quality materials. At least, where it is most important. Of course, there are some parts that are not as significant where you can cut down costs.

Try outsourcing

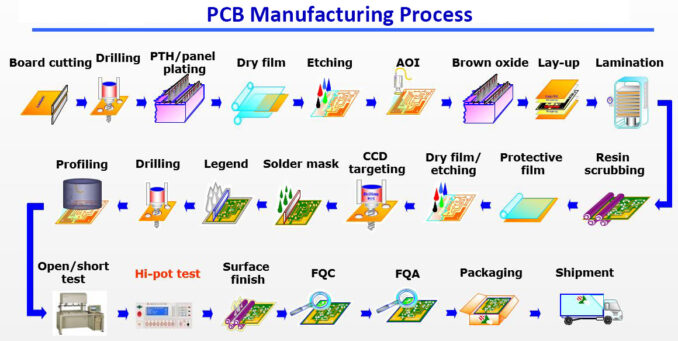

Source:season-pcb.com

Every new business that is formed in this industry has a very hard time developing enough to reach success. This is mostly because acquiring certain materials and components can be very difficult. Every company that offers such services are already too busy. For example, TSMC, the biggest semiconductor company right now has a very hard time keeping up with demand. I don’t think that TSMC would skip AMD, Intel, Nvidia, or other similar companies to satisfy smaller businesses.

Fortunately, you can always try outsourcing for components or certain steps of the PCB manufacturing process. Not only could this help you push your business forward, but you can end up with a PCB that is of high quality, efficient, and inexpensive as suggested by uetpcb.

Stick to standard components

I see a lot of printed circuit board manufacturers that try to find shortcuts and aim to be as unique as possible. Of course, if you have the will and the money to do that, go right ahead. But, if you want a safe and steady path to success in this industry, it is best to stick to the industry standards.

I would not recommend going out of your way to search for better or more efficient components for your PCBs. The most efficient methods have already been discovered in this industry, so there is no need to look for further improvements. This is especially true for younger companies. Those businesses still do not have the financial power to support such research and development.

This is why it is so important to just stick with the standard components in the industry. Do not deviate from them.

Try to stick to standard sizes too

Source:elecrow.com

In the previous tip, I wrote about why it is important to stick to the industry standards when it comes to components. But, if you want to save more money and to push the productivity of your company even further, I think it would be best to stick to the standard sizes too. There is no point to deviate from that standard path and look for something different.

If you want to create a unique PCB shape or size, it is going to cost you a lot more money and time from your employees.

This is important because if you do stick with the industry standards, you can easily find a machine nor equipment that will help you create a PCB with those generic sizes. The shapes and sizes that everyone else manufactures. There will be no equipment that can satisfy your unique type of printed circuit board.

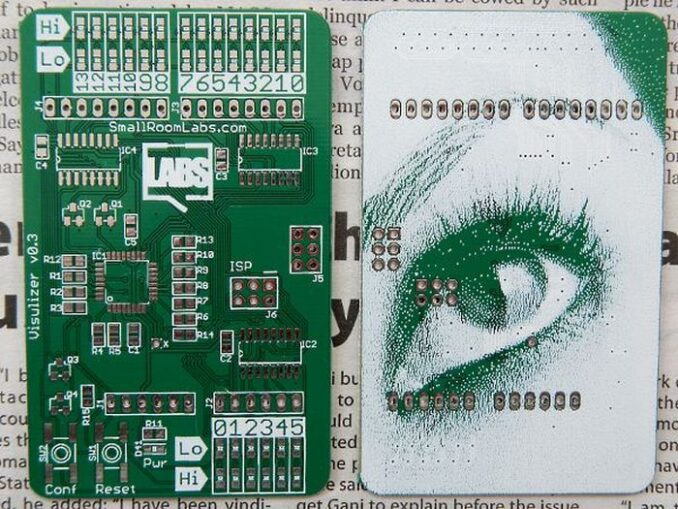

Label everything

Many experts believe that labels on PCBs should be mandatory. It makes the manufacturing process easier and simpler. With the proper labels, there will be no room for mistakes or confusion. So, make sure that the markings on your printed circuit boards do make sense.

It might not seem like much, but these kinds of tips in this industry can be very useful. I hope that you will find this article useful for your PCB manufacturing and assembly.